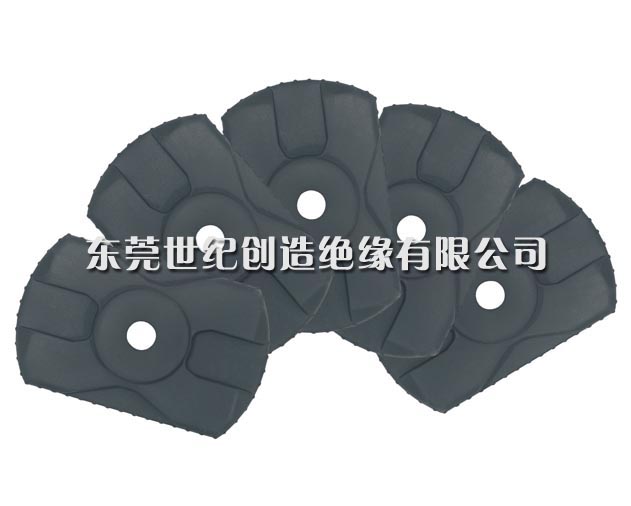

Introduction to Rubber Sponge

Release Date:2024-01-19 Click:1614

Rubber sponge. Sponge like porous structure of vulcanized rubber. There are three types of pores: open pores, closed pores, mixed pores, and micropores. Can be made into soft rubber or hard rubber products. Lightweight, soft, elastic, and resistant to heat transfer. It has functions such as shock resistance, shock mitigation, insulation, and sound insulation.

Features:

Made of synthetic rubber, it also has characteristics such as oil resistance, aging resistance, and chemical resistance. Widely used in industries such as automobiles, airplanes, chemicals, and daily necessities, as insulation, sound insulation, and shock-absorbing materials, as well as in the production of seat cushions, mattresses, medical machinery, hygiene products, sports equipment, etc. It can be made by adding foaming agents (such as ammonium carbonate, urea, azodiisobutyronitrile, etc.) to raw rubber or by mixing concentrated latex with air and then vulcanizing it. This is a processed sponge rubber product widely used in various industries

Structure:

All rubber, EVA (ethylene vinyl acetate), high styrene, and thermoplastic elastomers blended with rubber can be used to manufacture sponge rubber. The selection of specific adhesive types should be determined based on comprehensive consideration of the product's usage conditions, physical and chemical performance indicators, manufacturing methods, and processing performance.

Ordinary sponge rubber mainly uses natural rubber, styrene butadiene rubber, and butadiene rubber; Recycled rubber can be used for lower grade shoes (such as regular rubber soles); Advanced odorless insoles can be made with a combination of EVA/rubber, and micro porous soles can be made with a combination of EVA or high styrene and universal rubber, or with a blend of nitrile rubber and polyvinyl chloride; Oil resistant options include nitrile rubber, chloroprene rubber, nitrile rubber/polyvinyl chloride, epoxidized natural rubber, etc; When heat resistance and ozone aging resistance are required, EPDM rubber and silicone rubber can be selected; Foam sheets that are lightweight (with a relative density less than 1), high hardness (not less than 80), and excellent bending resilience often require a combination of plastic and rubber. It is difficult to achieve this comprehensive requirement solely by using sBs or rubber.

Considering the comprehensive factors such as service life, process, and cost, the ideal rubber types are EPDM rubber and chloroprene rubber; Natural rubber, styrene butadiene rubber, butadiene rubber, and their blends with plastics are commonly used in the manufacturing of civilian sponge rubber products. EPDM rubber and chloroprene rubber are commonly used in the manufacturing of industrial sponge rubber products.

Application:

Sponge rubber has a low density, excellent elasticity and flexibility, and good shock absorption, sound insulation, and thermal insulation properties. Sponge rubber is widely used in sealing, shock absorption, noise reduction, insulation, clothing, footwear, household appliances, printing and dyeing, fitness equipment, and ion exchange, among many other fields. Products such as car windshields, buffer pads, sealing gaskets for construction projects, insulation materials for weak current components, shock absorption materials, simple diving suits and shoes.

Next article:The main factors affecting the vulcanization process of rubber

Related news:

- Introduction to Rubber Sponge

- The main factors affecting the vulcanization process of rubber

- The principle of rubber foaming and how it is used for listening to voice during mixing in an internal mixer

- How to distinguish the quality of rubber foam strips?

- How rubber foam strips have a shock-absorbing effect

- Selection of Rubber Raw Materials for Rubber Sponge Products

- Why do we need to undergo secondary rubber vulcanization?

- What are the high-temperature resistance characteristics of rubber sponge materials reflected in?

- Common processing methods for sponge rubber foaming

- Why does rubber undergo significant changes in its properties after vulcanization