Why do we need to undergo secondary rubber vulcanization?

Release Date:2024-01-20 Click:1925

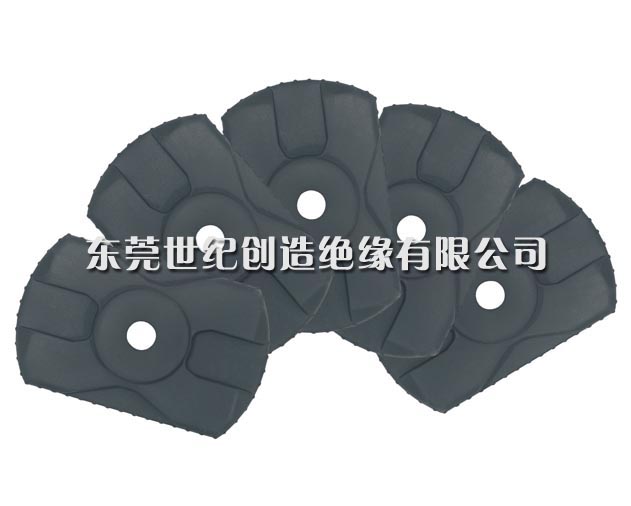

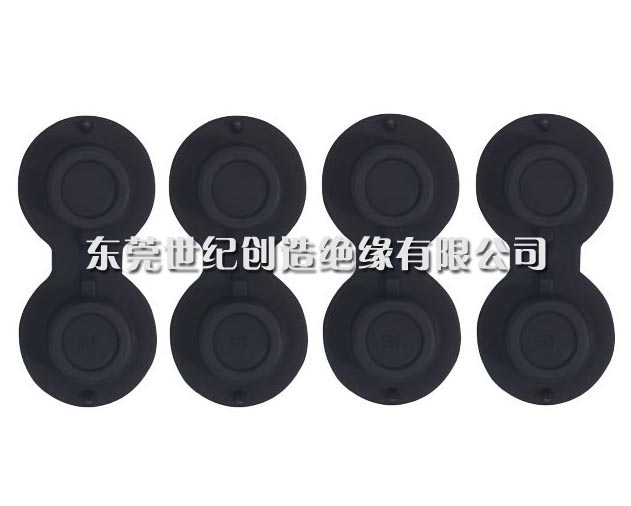

In a rubber vulcanization process, secondary vulcanization is required due to incomplete vulcanization or the production of products that affect the crosslinking density of the rubber during the vulcanization process. Secondary vulcanization, also known as post vulcanization. Commonly used for vulcanization of silicone rubber, fluororubber, and fluorosilicone rubber.

The effect of secondary rubber vulcanization: When silicone rubber is vulcanized with peroxide, the decomposition of peroxide triggers a polymer reaction, which generates low molecular weight compounds (such as benzene and benzoic acid) that exist in the rubber and will affect the mechanical properties of the rubber. Moreover, after the first stage of heating and molding, the cross-linking density of silicone rubber is insufficient, and further vulcanization reaction is needed to increase the density of silicone rubber. The tensile strength, resilience, hardness, swelling degree, density, and thermal stability have all been significantly improved compared to single vulcanization. If secondary vulcanization is not carried out, the performance of the produced silicone may be affected to some extent, and better performing products may not be obtained. In secondary vulcanization, there are actually very few peroxides, mainly increasing cross-linking through oxygen action.

So, the oven should be equipped with an air blowing device, and the glue should not be stacked too tightly. The low molecular weight substances such as HF released during the first stage of vulcanization of fluororubber will hinder rubber cross-linking and corrode metal parts, so secondary vulcanization is also necessary. In addition, fluororubber may undergo cyclization reactions to produce fluorinated rings, thereby further improving its heat resistance.

Related news:

- Introduction to Rubber Sponge

- The main factors affecting the vulcanization process of rubber

- The principle of rubber foaming and how it is used for listening to voice during mixing in an internal mixer

- How to distinguish the quality of rubber foam strips?

- How rubber foam strips have a shock-absorbing effect

- Selection of Rubber Raw Materials for Rubber Sponge Products

- Why do we need to undergo secondary rubber vulcanization?

- What are the high-temperature resistance characteristics of rubber sponge materials reflected in?

- Common processing methods for sponge rubber foaming

- Why does rubber undergo significant changes in its properties after vulcanization